Arthur Lynch | Mon Jul 28 2025

Reducing Procurement Costs: An Actionable Guide for Retailers

Ready to bring down your procurement costs? For retailers, this isn't about simply finding the cheapest deal. True cost reduction comes from a much smarter, more strategic approach. It's about building solid relationships with your suppliers, using real data to make informed choices, and planning your inventory with absolute precision to boost your bottom line.

Your Guide to Smarter Retail Procurement

For any retailer, but especially in the jewelry business, slashing procurement costs goes way beyond arguing over the price on a line sheet. The real wins come from a fundamental shift in how you think about buying, focusing on what’s known as the Total Cost of Ownership (TCO).

This means you have to look at the entire financial picture. The unit price is just one piece of the puzzle. As a retailer, you must also factor in logistics, shipping fees, import duties, payment terms, and even the cost of dealing with poor quality products. A cheap necklace that breaks easily will cost you more in returns, customer complaints, and reputation damage than a slightly more expensive, well-made one ever would.

This way of thinking is a huge leap from the old-school purchasing model. In the past, procurement was often a reactive role, squeezed by inflation and economic downturns, with a laser focus on cutting costs at all costs. Today, savvy retailers see procurement as a key driver of growth and innovation, not just a department that manages expenses. You can see how these trends are reshaping the industry over on Esker.com.

Beyond Price: A Proactive Approach

To get ahead, you need to adopt a strategic sourcing mindset. Stop just reacting when you’re low on stock. Instead, focus on proactively building a supply chain that's both resilient and cost-effective.

So, how do you do that? It comes down to a few key practices:

- Make Data-Driven Decisions: Use your sales history and market trends to forecast what you'll need and when. This helps you avoid the twin perils of tying up cash in overstock and missing out on sales because an item is sold out.

- Forge Real Supplier Partnerships: Shift your supplier relationships from purely transactional to truly collaborative. A great partner can offer you better payment terms, give you first dibs on new designs, and show flexibility when you're slammed during peak season.

- Optimize Your Processes: Take a hard look at your entire purchasing workflow, from discovery to payment. You’d be surprised by the small inefficiencies that quietly inflate your costs over time.

Here's a classic retailer mistake: chasing the absolute lowest per-unit price without weighing the hidden costs. A piece that costs a dollar more from a reliable supplier—one who offers 60-day payment terms and ships in three days instead of three weeks—is almost always the more profitable choice for your business.

Think of this guide as your first step away from simple tactical buying. For jewelers, mastering the art of sourcing is a massive competitive advantage. You can get a running start by checking out our guide on finding jewelry wholesale suppliers.

The Art of the Deal: Modern Procurement Cost Levers

To really get a handle on your spending, it helps to break down where the savings opportunities are. It's not just about negotiating the sticker price anymore. The real value for a retailer is found by pulling different "levers" across your entire procurement process.

The table below outlines these key levers, moving from the traditional focus on unit price to a more holistic view of total value.

Key Levers for Reducing Total Procurement Costs

| Cost Lever | Description | Example for a Retailer |

|---|---|---|

| Unit Price Reduction | The classic approach. Directly negotiating a lower price per item with suppliers. | Securing a 5% discount on a bulk order of sterling silver chains by committing to a larger volume. |

| Payment Term Optimization | Improving cash flow by negotiating longer payment windows (e.g., from Net 30 to Net 60). | Negotiating 60-day payment terms for a large holiday order, freeing up cash for marketing campaigns. |

| Logistics & Freight Savings | Consolidating shipments, choosing slower/cheaper shipping methods, or working with suppliers who offer better rates. | Combining orders from two different suppliers in the same region into a single consolidated air freight shipment. |

| Quality Improvement | Reducing costs associated with returns, repairs, and customer complaints by sourcing higher-quality products. | Switching to a supplier with a <1% defect rate, saving hours of customer service time and replacement costs. |

| Process Efficiency | Automating or simplifying the purchasing workflow to reduce administrative overhead and labor costs. | Using an inventory management system to automate reordering for core items, saving the buyer 5-10 hours per week. |

By looking at procurement through this wider lens, you can identify hidden costs and unlock savings that go far beyond what a simple price negotiation could ever achieve.

Holiday Procurement Planning: A Retailer's Edge

For retailers, timing is everything, especially when it comes to major shopping holidays. A well-executed procurement calendar is your single best defense against last-minute price hikes and the dreaded "out of stock" sign during your busiest seasons.

For example, to be ready for the end-of-year holiday madness (Black Friday, Christmas), you absolutely need to be finalizing those orders by late summer or early fall. This buffer lets you sidestep the peak-season shipping surcharges and gives your suppliers time to manufacture without rushing.

Apply that same logic to other key dates on the retail calendar:

- Valentine's Day (February 14): Get your orders for heart pendants and romantic gift sets locked in by late October. This ensures everything arrives and is ready for your shelves long before the January shopping rush begins.

- Mother's Day (May): Another critical date. Lock in orders for popular gift items by the end of February to avoid the spring shipping crunch and ensure on-time delivery.

- Diwali (October/November): For retailers serving communities that celebrate Diwali, placing orders by July or August is crucial to navigate potential international shipping and customs delays.

- Lunar New Year (January/February): This is critical. Many factories in Asia shut down completely for a week or more. You must have all your orders placed, produced, and shipped before these closures start. Your deadline should be early December at the absolute latest.

Build Stronger Supplier Relationships to Unlock Savings

Many retailers see procurement as a zero-sum game—a constant battle where for you to win on price, your supplier has to lose. But the most effective way to reduce procurement costs isn't through conflict, but collaboration. When you stop treating suppliers like interchangeable vendors and start building genuine, long-term partnerships, you unlock savings that simple haggling could never touch.

Your suppliers aren't just order-takers; they're your partners in bringing beautiful jewelry to your customers. When they see you as a reliable, steady retail partner, they become invested in your success. This creates a powerful win-win dynamic. They’re more motivated to offer you better pricing, flexible terms, and top-notch service because your growth is good for their business, too.

Put yourself in their shoes for a second. A huge one-time order from a demanding, difficult customer is far less attractive than consistent, predictable business from a retailer who pays on time and communicates clearly. That goodwill is a massive, and often overlooked, asset in your negotiation toolkit.

Consolidate Your Spending to Maximize Your Clout

One of the most practical ways for a retailer to strengthen these relationships and get better pricing is to consolidate your spending. Instead of spreading your budget thinly across a dozen different suppliers, figure out who your best partners are and funnel more of your business their way.

This strategy pays off in a few key ways when it comes to reducing procurement costs:

- Serious Volume Discounts: When you concentrate your purchasing power, you gain real leverage. A supplier is much more willing to give you a 10-15% price break when you can commit to larger, more consistent orders.

- Lower Administrative Headaches: Fewer suppliers mean fewer invoices to chase, fewer contracts to manage, and way less time spent on back-and-forth emails. Those operational efficiencies add up to real cost savings for your retail business.

- VIP Treatment: Becoming a key account often puts you at the front of the line. This can translate into faster shipping, priority access to new designs, and a dedicated person to call when you need help.

For a jewelry business, this might look like sourcing the bulk of your sterling silver chains, clasps, and popular gemstone cabochons from one or two trusted partners instead of five or six. That increased order volume instantly makes you a more valuable client, opening up conversations about price, payment terms, and even co-developing exclusive pieces.

Move Beyond Price to Create Value-Driven Partnerships

A truly strategic supplier relationship goes far beyond the price-per-unit. The conversation needs to evolve into one about shared goals and long-term value. This means opening up clear lines of communication and working together on everything from sales forecasting to product packaging.

For example, by sharing your upcoming promotional calendar with your supplier, you give them a heads-up. They can plan their production schedule accordingly, which means you won't have to place expensive, last-minute rush orders to restock for Valentine's Day or the holiday season.

It’s a huge misconception that a supplier relationship is all about getting the lowest price. A partner who works with you on custom packaging to lower your shipping weight or offers “buy now, pay later” terms during your slow season provides far more value than a supplier who just undercuts everyone else on the initial quote.

This collaborative mindset is more important than ever. The definition of a "win" in procurement is expanding beyond just cutting costs. Today, it's about cost avoidance, sustainability, and overall supply chain health. In fact, recent data shows that around 66% of procurement leaders expect ESG (Environmental, Social, and Governance) factors to heavily influence their sourcing decisions. You can read more about these evolving procurement strategies in a great analysis from Supply Chain Dive. This shift makes it critical to partner with suppliers whose values align with your brand—a factor that can be just as important as price.

At the end of the day, building strong supplier relationships is an investment. It takes transparency, clear communication, and a genuine commitment to mutual success. The returns, however—in the form of lower costs, better efficiency, and a more resilient business—are well worth the effort and are a cornerstone of any serious strategy for reducing procurement costs.

Use Technology for Smarter, Data-Driven Buying

In the retail jewelry business, relying on gut feelings and old spreadsheets just doesn't cut it anymore. If you want a serious edge, the single most powerful tool you have for reducing procurement costs is technology. Embracing data-driven tools lets you shift from simply reacting to market changes to proactively sourcing inventory in a way that directly fattens your bottom line.

This doesn't mean you need to sink a fortune into some massive, complex system. The right tech can be as simple as a solid inventory management platform or a more complete e-procurement solution. The real goal is to get a crystal-clear, real-time view of where your money is going.

Good software automates the tedious stuff, tracks every dollar spent, and can even flag rogue purchases before they snowball. When you have hard data on supplier performance—like on-time delivery rates or defect percentages—you're no longer guessing. You're making decisions based on facts.

From Guesswork to 'Should-Cost' Analysis

One of the biggest wins from using procurement tech is the ability to do a proper 'should-cost' analysis. This is a total game-changer for your supplier negotiations. Instead of just taking a supplier's price at face value, you can build your own model of what a piece should cost based on current material prices, labor, and other market factors.

For a jewelry retailer, this means actively tracking the spot price of sterling silver or the market rate for specific grades of gemstones. When you walk into a negotiation armed with this information, you’re not just haggling. You’re leading an informed discussion. You can confidently say, "Based on the current commodities market, we were projecting a price point closer to X for this order."

This data-first approach completely changes the dynamic. It gives you the power to secure better terms because your requests are backed by solid evidence, not just a hope for a lower price.

Practical Tech for Jewelry Retailers

Even smaller shops can get their hands on affordable technology to streamline how they buy. Many modern platforms offer tiered pricing, so you can access powerful features without a massive upfront investment.

Here’s a look at how different tools can make a difference:

- Inventory Management Software: This is your foundation. It keeps tabs on stock levels, automates reorders for your best-sellers, and uses sales data to forecast what you'll need next. That alone prevents you from tying up cash in overstock or losing sales because you ran out of a popular item.

- E-procurement Platforms: These systems bring your entire purchasing process under one roof. They create a central hub for finding suppliers, placing orders, and handling payments, which dramatically cuts down on administrative headaches and gives you a complete overview of your spend.

- Supplier Management Tools: Often built into larger systems, these tools help you score and track supplier performance. You can set your own metrics for things like price accuracy, quality control, and shipping speed.

Adopting these tools is really about creating a single source of truth for your spending. When all your purchasing data is in one place, you start seeing trends and opportunities you’d otherwise miss. For example, you might discover two departments are buying similar clasps from different suppliers at wildly different prices—an easy win for consolidation.

Recent industry studies show just how much of an impact this can have. Companies using AI-driven sourcing and automation have managed to expand their sourcing reach and make smarter buys. By using tech to grow their sourcing pipelines without having to grow their teams, these organizations have seen huge efficiency gains. To see what's coming next, you can explore the full predictions on ivalua.com.

Ultimately, bringing technology into your buying process is about making smarter, more profitable decisions. It elevates procurement from a simple cost center to a strategic part of your business that actively drives growth. As you look at different tools, always ask how each one helps create a clearer financial picture. If you're ready to take the next step, our guide on strategic sourcing for jewelry offers more specific advice on applying these principles to your business.

Master Your Seasonal Procurement Calendar

In the jewelry business, timing isn't just a part of the game—it's everything. I've seen countless retailers pay a steep price for reactive buying. A well-oiled procurement calendar is your single best defense against this, helping you reduce procurement costs by shifting your strategy from last-minute panic to proactive planning.

Think of it this way: your planning has to extend far beyond your own stockroom. You're dealing with a global supply chain. That means accounting for manufacturing lead times, navigating the complexities of international freight, and clearing customs. These steps can easily add weeks, if not months, to your timeline. Planning ahead is how you sidestep the killer express shipping fees and pre-holiday surcharges that eat into your margins.

When you get your timing right, you're always a step ahead. It’s not just about having enough inventory for Black Friday. It's about building a resilient, predictable business model that directly strengthens your bottom line.

Planning for Global Holidays and Peak Seasons

To really get a handle on your costs, you have to think globally. Your calendar can't just track the holidays in your own country; it needs to account for major events that impact your suppliers' ability to produce and ship your goods. These global peaks create bottlenecks that can stall your orders and drive up expenses.

Let’s walk through a few real-world examples for key jewelry seasons:

-

Valentine's Day (February 14): This is a monster holiday for retailers. To sidestep the post-New Year's chaos, you absolutely need to finalize those orders for heart pendants and earring sets by late October. This gets your inventory delivered in January, leaving you ample time for photography, marketing, and merchandising.

-

Mother's Day (Mostly May): Another huge date on the retail calendar. I recommend starting your sourcing conversations in January. Your goal should be to lock in final orders by the end of February to avoid the springtime shipping crunch.

-

Lunar New Year (January/February): This one is non-negotiable for anyone sourcing from Asia. Many factories shut down completely for at least a week, sometimes two. Your product must be manufactured and on a boat before the closures start. That means your drop-dead deadline for placing orders is early December.

-

Diwali (October/November): If you serve a community that celebrates Diwali, planning ahead is critical. Customs can get bogged down during this busy season, so placing your orders by July or early August is a smart move.

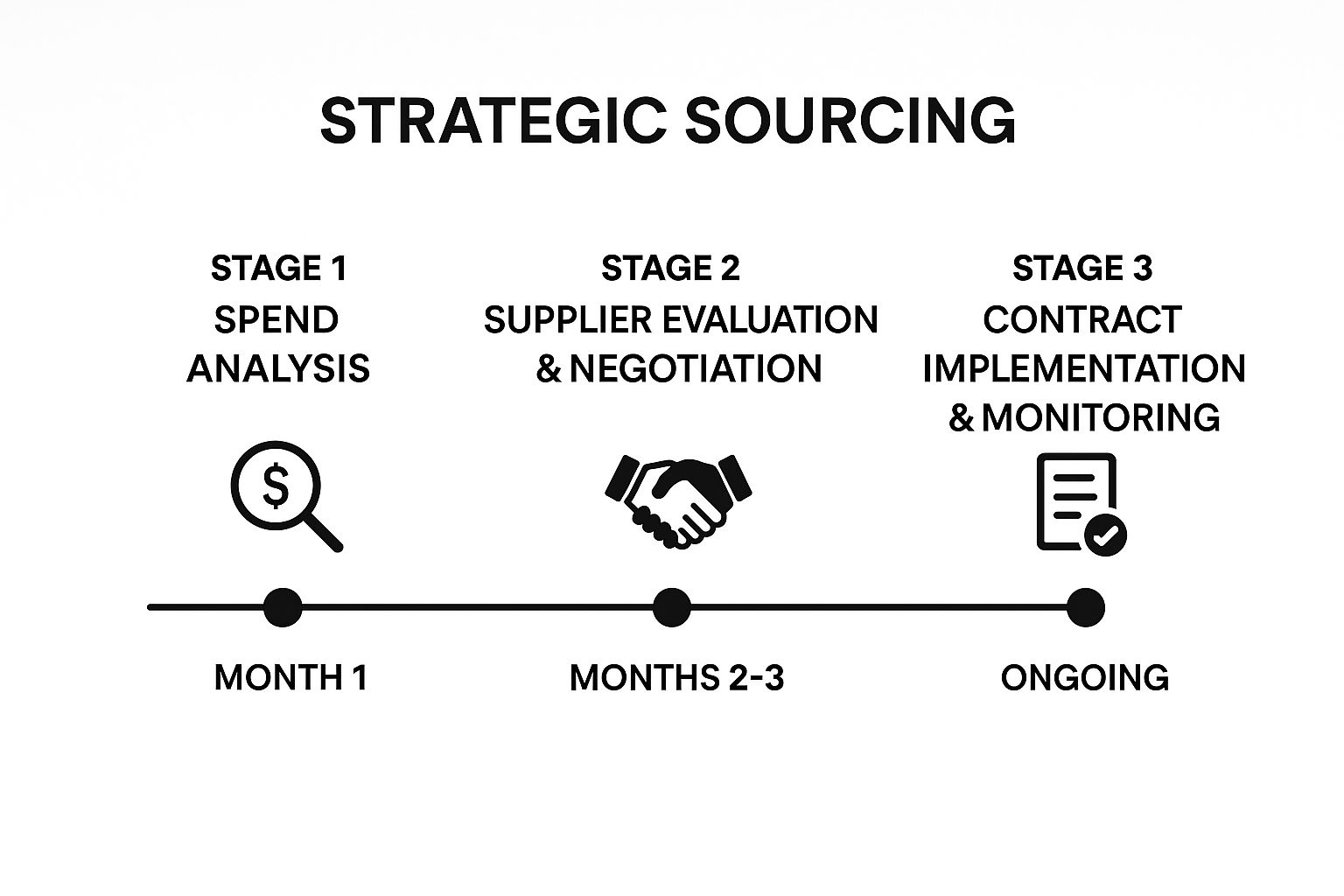

This visual breaks down the bigger picture of strategic sourcing, which is the foundation for all this calendar work.

As you can see, smart procurement isn't a one-and-done deal. It's a multi-month process of analysis, negotiation, and careful monitoring.

To make this even more practical, here is a quick-reference table for your procurement planning.

Global Holiday Procurement Planning Calendar for Retailers

This table outlines suggested timelines for major retail holidays. Use it as a starting point to build your own custom calendar, ensuring you order early enough to secure better pricing and guarantee on-time delivery.

| Holiday/Season | Typical Peak Sales | Recommended Final Order Deadline | Key Cost-Saving Consideration |

|---|---|---|---|

| Valentine's Day | Late Jan - Feb 14 | Late October | Avoids post-New Year rush and premium pricing. |

| Mother's Day | Late Apr - Early May | End of February | Skips the spring shipping surge and potential delays. |

| Lunar New Year | N/A (Factory Shutdowns) | Early December | CRITICAL: Ensures production is finished before factories close. |

| Diwali | October/November | July/Early August | Bypasses pre-holiday customs bottlenecks. |

| Black Friday/Cyber Monday | Late November | Mid-to-Late June | Secures production slots before the holiday manufacturing frenzy. |

| Christmas | December | Early July | Avoids peak season freight surcharges and ensures pre-December arrival. |

Remember, these are guidelines. The more you work with your suppliers, the more you can refine these dates to perfectly match your business needs and their production schedules.

Advanced Scheduling Strategies for Retailers

Simply marking dates on a calendar is a great start, but the pros use more advanced tactics to gain an edge. These strategies are all about locking in favorable terms and managing your inventory flow like a finely tuned machine, which is another great way to reduce procurement costs.

One of the most powerful moves a retailer can make is negotiating a blanket order with staggered deliveries. Here's how it works: you commit to buying a large quantity of a core item—say, your best-selling sterling silver chain—to get a fantastic volume discount. But instead of getting it all at once, you arrange for your supplier to send smaller shipments throughout the year.

This strategy is a true win-win. Your supplier gets the security of a large, predictable order, and you get an incredible price without tying up cash and warehouse space in inventory you don't need yet. It's a brilliant way to improve cash flow while still getting bulk-order perks.

Another key is to stay plugged into your suppliers' schedules beyond just the big holidays. Ask them about regional festivals or national holidays that might cause unexpected shutdowns. This is where having a strong relationship really pays off—a good partner will give you the heads-up you need to plan around any potential disruptions.

Ultimately, mastering your seasonal calendar transforms procurement from a back-office chore into a strategic advantage. When you plan proactively, you insulate your business from volatile prices and supply chain shocks, ensuring you always have the right product, at the right time, and—most importantly—at the right cost.

Fine-Tune Your Inventory to Boost Your Cash Flow

Let’s be honest: one of the biggest, quietest profit killers in retail is excess inventory. Every unsold necklace or bracelet sitting in your back room is cash you can't touch—money that could be fueling your marketing, developing new designs, or simply growing the business. Smart inventory management isn't just about being tidy; it's a powerful strategy for reducing procurement costs by making sure you only buy what you need, right when you need it.

When you get this right, your inventory stops being a liability and starts acting like a lean, cash-generating asset. Aligning what you buy with what you'll actually sell helps you dodge the heavy costs of overstocking, like storage fees, insurance, and the dreaded markdowns you have to take just to clear out old products.

Adopt Smarter Inventory Models

For most jewelry retailers, the old-school approach of buying in bulk and just hoping for the best is a recipe for disaster. Today's most successful businesses focus on being agile and efficient. A perfect example of this is the Just-in-Time (JIT) model.

The whole point of JIT is to get goods from your suppliers as close as possible to the moment you need them for a sale. In the jewelry world, this could mean ordering smaller, more frequent batches of trendy pieces instead of placing one massive seasonal order. It’s a game-changer for minimizing how much of your capital is tied up in stock that's just sitting there.

Of course, JIT isn't a silver bullet. It demands incredibly reliable suppliers and spot-on demand forecasting. One hiccup in the supply chain can lead to empty shelves, so it's a model you have to ease into carefully.

A key takeaway: Carrying excess inventory costs real money. Industry experts estimate that holding costs can eat up as much as 25-30% of your inventory's value each year. That figure includes storage, insurance, items becoming outdated, and the capital you have tied up. Getting your stock levels right is one of the most direct ways to improve your cash flow.

Improve Demand Forecasting to Prevent Overstock

Good forecasting is the engine that drives smart buying. Instead of relying on gut feelings, it's time to dig into your sales data to make decisions with confidence. Look at your past sales, pinpoint your bestsellers, and pay close attention to what sells when.

- Track Your Winners and Losers: Your own data is your best friend. Figure out which items fly off the shelves and which ones are collecting dust. Double down on your winners and be ruthless about cutting back on—or even discontinuing—your losers.

- Factor in Seasonality: Think beyond the major holidays. Do you see a surge in earring sales around prom season? A bump in birthstone jewelry sales every month? Use these "micro-seasons" to fine-tune your orders.

- Talk to Your Suppliers: Don't keep your forecasts a secret. When you share your projections with your key suppliers, it gives them a heads-up on your needs, which can lead to better product availability and sometimes even better pricing for you.

By aligning your buying with solid forecasts, you avoid the costly mistake of overstocking. This frees up cash that would otherwise be gathering dust on a shelf. For more ideas on getting a handle on your stock, check out our guide on strategic jewelry inventory management.

Use Financial Tactics to Free Up Capital

Beyond just managing your physical stock, a few savvy financial moves can seriously improve your cash flow and lower the real cost of your inventory. A great place to start is with your payment terms.

Simply negotiating better terms with your suppliers can have a huge impact. For instance, shifting from Net 30 (payment due in 30 days) to Net 60 terms gives you an entire extra month to sell your jewelry before the bill is due. This works like a short-term, interest-free loan from your supplier and can dramatically improve your working capital.

You can also look into dynamic discounting. This is where a supplier might offer you a small discount—say, 1-2%—for paying an invoice early. While it might not sound like much, these small discounts can add up to a significant amount over a year, directly chipping away at your procurement costs.

Common Questions About Lowering Your Jewelry Procurement Costs

When you're running a jewelry business, trying to get the best price on your inventory without sacrificing quality can feel like a constant balancing act. It's a challenge every retailer faces. Let's walk through some of the most common questions I hear from business owners and break down the answers with practical, real-world advice.

How Can a Small Retailer Possibly Negotiate Better Prices?

It’s easy to feel like you don’t have much leverage when you're a smaller shop competing with big chains. But you have more negotiating power than you realize. The key isn't just asking for a random discount; it's being prepared and strategic.

Instead of simply asking for a lower price, walk into the conversation armed with your own data. Show your supplier your sales projections. Explain exactly how their pieces fit into your growth strategy for the coming year. Sometimes, it helps to consolidate your orders for your best-selling, core items. This creates a more attractive order volume, even for a smaller business. Suppliers are often looking for reliable, long-term partners, not just massive one-time purchases.

Here's a pro tip: Shift your focus from the per-unit price to the Total Cost of Ownership (TCO). A supplier might be firm on their per-item cost but could be flexible on other things. Could they offer a discount on shipping? Or maybe better payment terms, like Net 60 instead of Net 30? Getting more favorable terms directly improves your cash flow, which is a huge win.

What’s the Real Difference Between Cost Reduction and Cost Avoidance?

This is a really important distinction, because it changes how you measure your success and report your savings.

-

Cost Reduction is a straightforward, measurable drop in what you actually spend. If you were paying $10 for a pair of earrings and you negotiate that down to $9, you’ve achieved a $1 cost reduction. These are hard savings that directly impact your bottom line.

-

Cost Avoidance is about preventing your costs from going up. Let's say your supplier announces a 10% price increase, taking that same pair of earrings from $10 to $11. If you successfully negotiate to keep your price at $10, you've "avoided" a $1 cost increase. It doesn't lower your current expenses, but it's absolutely critical for protecting your profit margins.

Both are vital for a smart procurement strategy. Tracking them separately gives you a much clearer picture of the financial impact of your purchasing efforts.

How Should I Plan My Procurement for Different Holidays?

Smart holiday planning is all about working backward. You have to think beyond when your customers start shopping and consider the realities of the global supply chain, including when factories are slammed with orders or even closed completely.

I always tell retailers to think of it as a tiered schedule based on the holiday and where your suppliers are located.

| Holiday / Event | Ideal Time to Place Your Order | Why It Matters & A Key Tip |

|---|---|---|

| Christmas/Black Friday | June to Early July | This is the absolute peak season for manufacturing worldwide. Ordering this early gets you a spot in the production queue before factories get overwhelmed and helps you dodge the worst of the peak-season shipping surcharges. |

| Valentine's Day | Late October | By placing your order before the New Year chaos, you ensure your products are shipped and in your hands for merchandising in January. You'll be ready long before the customer rush starts. |

| Lunar New Year | Early December (at the latest) | This one is non-negotiable. Many factories in Asia shut down for weeks. Your order needs to be fully produced and shipped out before the closures start, or you're looking at major delays. |

| Mother's Day | Late February | This timing lets you get ahead of the general spring shipping surge. It ensures your pieces arrive on time for what is easily one of the biggest gifting holidays of the year. |

Always remember to tailor this calendar to your specific product assortment and your suppliers' locations. And please, always build in a buffer for unexpected shipping or customs delays—they happen. Getting your timing right is one of the most effective ways of reducing procurement costs, because it saves you from paying the high price of last-minute urgency.

Ready to put these strategies into practice? JewelryBuyDirect gives you access to direct-from-factory pricing and a huge selection, helping you lower your procurement costs without giving up on quality or the latest trends. Explore our catalog and see how our efficient supply chain can help boost your profitability.

to show code

to show code