Arthur Lynch | Fri Jan 09 2026

What is PVD Coating on Jewelry? A Sourcing Guide for Businesses

When you're sourcing jewelry for your business, you've likely come across the term PVD coating. Understanding what it is and why it matters is critical for curating a high-quality, affordable collection that keeps customers happy and your business profitable.

PVD, or Physical Vapor Deposition, is a modern vacuum coating process that molecularly bonds a thin film of metal to a base material, typically stainless steel or titanium. The result isn't just a surface layer; it's a new, fused finish that is incredibly durable, corrosion-resistant, and vibrant. For businesses focused on fashion accessories, this is a game-changing technology.

What PVD Coating Means for Your Jewelry Business

For a business owner, understanding PVD is key to building a reliable and profitable inventory. Think of traditional gold plating like a coat of paint on a car. It looks great initially, but it’s vulnerable to chipping, flaking, and fading with everyday wear.

PVD, however, is more like anodizing aluminum. The color becomes an integral part of the metal's surface, creating a molecular bond that's exceptionally tough to break.

This process gives your business a significant competitive advantage. You can confidently source and sell pieces that not only look premium in your product photos but also withstand the demands of daily life. It directly addresses common customer pain points like tarnishing, fading, and skin irritation, which are frequent issues with lower-quality plated accessories.

Why PVD Matters for Sourcing Affordable, High-Quality Accessories

When you stock PVD-coated jewelry, you're investing in inventory with clear advantages that directly impact your bottom line. These pieces are engineered for longevity, which translates to satisfied customers, fewer returns, and a stronger brand reputation. The PVD process elevates an affordable base metal like stainless steel into a product that has the look and feel of a luxury item but with far greater durability.

Here's what that means for your business:

- Superior Durability: The finish is highly resistant to scratches and won't corrode or tarnish when exposed to sweat, water, or perfume. Your products stay looking new, enhancing their perceived value over time.

- Safe for Sensitive Skin: PVD coatings are inert and biocompatible. This makes them a fantastic, worry-free option for customers who typically avoid plated jewelry due to allergies.

- Affordable Luxury: You can offer the rich look of gold, rose gold, or black at a price point that is accessible to your target market while protecting your profit margins.

Focusing on sourcing PVD-coated pieces allows your business to build a collection known for being both beautiful and resilient. In a competitive market, a reputation for quality is a powerful asset. It drives repeat business and sets you apart from retailers selling cheaper, traditionally plated accessories that quickly degrade.

Let's quickly recap the core business benefits of adding PVD-coated jewelry to your product line.

PVD Coating At-a-Glance for Your Business

This table breaks down why PVD is a strategic choice for any business aiming to build a brand around quality and customer satisfaction in the jewelry and fashion accessories space.

| Feature | Description and Business Benefit |

|---|---|

| Exceptional Durability | The coating is molecularly bonded to the base metal, making it highly resistant to scratches and wear. Benefit: Reduces returns and quality complaints, boosting customer trust. |

| Corrosion & Tarnish Proof | The finish withstands exposure to sweat, water, and humidity without fading or tarnishing. Benefit: Your products maintain their premium look, leading to higher customer satisfaction. |

| Hypoallergenic Finish | The coating is inert and biocompatible, making it safe for sensitive skin. Benefit: Opens up your market to customers who cannot wear traditionally plated jewelry. |

| Vibrant Color Options | Achieves rich, consistent colors like gold, rose gold, and black. Benefit: Allows you to offer on-trend styles with the appearance of precious metals, increasing perceived value. |

| Eco-Friendly Process | PVD is a dry, clean vacuum process that produces no hazardous waste. Benefit: Appeals to environmentally conscious consumers and aligns with sustainable business practices. |

Ultimately, sourcing PVD jewelry is a strategic decision. It’s about building a brand that customers associate with lasting value and quality they can rely on for years.

How PVD Creates Stronger Jewelry Finishes

To confidently source and market PVD jewelry, it’s helpful to understand how it's made. The science behind the process is the reason these pieces dramatically outlast traditionally plated alternatives. Grasping this allows you to communicate the value to your customers with genuine authority.

Think of PVD coating as a high-tech fusion process. Instead of simply dipping a piece into a colored solution, PVD physically bonds a microscopic layer of metal onto the base. It is not a paint or a dip—it is a fundamental, atomic-level transformation of the jewelry's surface.

The PVD Process From Start to Finish

The entire process occurs inside a specialized vacuum chamber. This controlled environment is crucial because it eliminates air and impurities that could compromise the finish. Each step is precisely managed to achieve a flawless, consistent result.

Here’s a breakdown of how it works:

- Immaculate Cleaning: First, the base jewelry—typically a durable material like high-grade stainless steel—is meticulously cleaned. Any microscopic speck of dust or oil can prevent the PVD layer from bonding correctly, so the pieces undergo several cleaning and drying cycles.

- Loading and Sealing: The clean jewelry is carefully placed on racks inside the PVD chamber. The door is sealed, and powerful pumps remove all the air, creating a near-perfect vacuum.

- Heating and Ionic Blasting: The jewelry is heated to a precise temperature. A high-voltage current then bombards the surface with ions, creating a micro-textured surface ideal for the new coating to adhere to.

- Vaporization and Bonding: A solid piece of coating material, such as titanium or zirconium (the "target"), is vaporized into a plasma using an electric arc. By introducing specific gases like nitrogen, this metallic vapor reacts and bonds, molecule by molecule, to the jewelry, forming a dense, incredibly hard new surface.

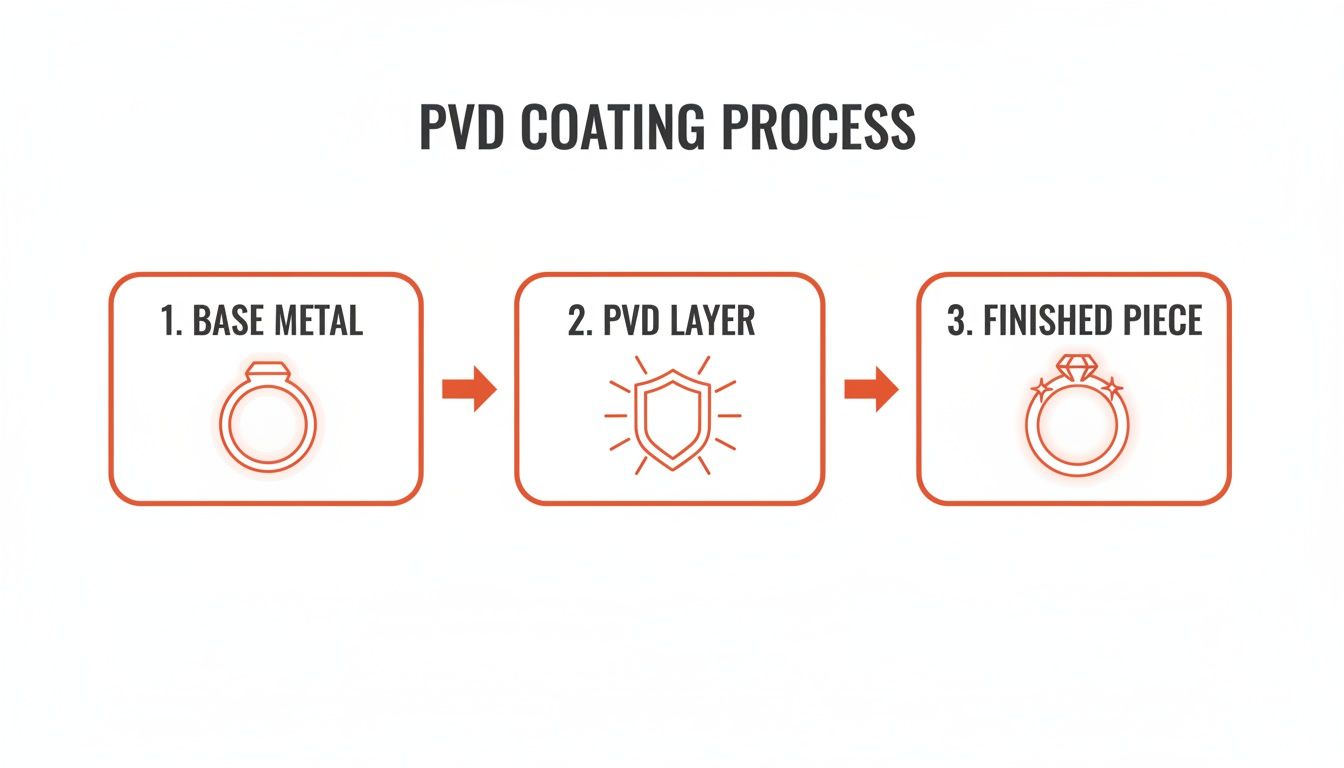

The diagram below provides a visual of how a simple base metal becomes a durable, beautifully finished piece ready for your inventory.

As shown, the PVD layer isn't just sitting on top; it has become a fully integrated shield fused directly onto the base.

Why This Process Matters for Quality

The rigorous, multi-step nature of PVD is what makes it superior for creating high-quality, affordable jewelry. The vacuum chamber ensures a pure application, and the atomic bonding results in a finish that resists scratches, wear, and corrosion that would quickly damage traditional plating.

The result isn't just a color. It's a new, atomically bonded surface that is incredibly hard and biocompatible. This is why PVD-coated stainless steel can handle daily wear, sweat, and water without tarnishing or fading.

Understanding this process helps you source better products. The best base metals for PVD, like surgical-grade 316L stainless steel, are chosen for their inherent strength and corrosion resistance. For a deeper dive, you can learn more about 316L stainless steel jewelry in our guide.

When you source a piece made from a quality base metal and finished with PVD, you know you're acquiring a long-lasting, high-value product. This knowledge boosts your credibility and your business's reputation for quality.

The Top 5 Business Advantages of PVD Jewelry

Knowing the science is important, but what does PVD coating actually do for your business? For any retailer or brand owner, inventory selection is a critical decision that impacts your bottom line, customer loyalty, and brand perception.

Stocking PVD jewelry is more than just adding a new product line; it's a strategic move to enhance your business. Let's break down the five key advantages that make PVD-coated pieces a must-have for your inventory.

1. Superior Durability Slashes Your Return Rate

Let’s be direct: returns are costly and damage customer trust. A product that chips, tarnishes, or fades quickly leads to refunds and, more importantly, a lost customer. PVD coating is the ideal solution to this problem.

Because the finish is molecularly bonded to the base metal, it withstands the rigors of daily life—scratches, bumps, and constant friction. This directly translates to fewer customer complaints, a significant reduction in returns, and a reputation for selling quality jewelry that lasts.

2. A Full Spectrum of Premium Colors at an Affordable Cost

Every business owner knows the appeal of precious metals, but solid gold is often not a viable option for affordable fashion accessories. PVD provides the best of both worlds: the high-end look without the prohibitive cost.

You can easily source pieces with the rich tones of 14K or 18K gold, the soft blush of rose gold, or a modern, sleek black finish. This versatility allows you to capitalize on trends and cater to diverse customer tastes while maintaining accessible price points and healthy profit margins. This is achieved using materials like titanium nitride and zirconium nitride, which produce beautiful, long-lasting colors.

3. Hypoallergenic Properties Widen Your Customer Base

Skin sensitivity is a significant concern for many consumers. A large portion of the population reacts to common metals like nickel, making most traditionally plated jewelry unsuitable for them. This represents a large, underserved market segment.

PVD coatings, however, are biochemically inert. Materials like titanium nitride are biocompatible, creating a safe, protective barrier between the base metal and the wearer's skin.

By sourcing hypoallergenic PVD jewelry, you instantly become a preferred supplier for customers who have struggled to find fashionable accessories they can wear without irritation. This is a powerful way to build brand loyalty and capture a niche market.

4. A Smarter, More Sustainable Choice

Modern consumers are increasingly conscious of the environmental impact of their purchases. A compelling sustainability story is no longer just a bonus; it's a key selling point that can differentiate your brand.

The PVD process has a distinct advantage here. Unlike traditional electroplating, which often involves vats of harsh chemicals like cyanide, PVD is a clean, dry vacuum process that generates virtually no waste. Sourcing PVD products aligns your business with responsible manufacturing—a narrative that resonates with today's consumers.

5. Higher Perceived Value Drives Higher Profits

Ultimately, business success depends on profitability. PVD-coated jewelry looks and feels far more luxurious than its cost price suggests. The finish is flawless, the colors are rich, and the durability is what consumers expect from high-end accessories.

This is why many leading fashion brands have adopted PVD. A "gold-tone" titanium nitride PVD coating can be many times more resistant to wear than typical gold electroplating, maintaining its appearance for years, while a flash-plated item might look worn in months. You can find technical validation in research from the Santa Fe Symposium, which confirms both the longevity and the cleaner process of PVD.

This undeniable quality allows you to position your jewelry as a premium-yet-affordable option, justifying a better price point and directly increasing your profit margins.

Comparing PVD To Other Common Jewelry Finishes

As a business owner, making intelligent sourcing decisions requires knowing your options. By understanding the different types of jewelry finishes available, you can curate an inventory that delivers on your brand's promise of lasting quality and style.

Let's compare Physical Vapor Deposition (PVD) with other common coatings to see how they stack up from a business perspective.

This isn’t just technical information; it’s practical knowledge that helps you understand why a PVD-coated stainless steel piece is a superior product compared to a flash-plated brass item. Knowing these differences empowers you to select the right inventory, set confident prices, and clearly communicate the value to your customers.

PVD Versus Traditional Gold Plating

Traditional gold plating, or electroplating, involves dipping jewelry into a chemical solution containing dissolved gold and using an electric current to attach a thin layer to the surface. While effective for achieving a gold look at a low cost, the bond is superficial.

Think of it as a temporary finish. Over time, the plated layer will inevitably chip, flake, or wear away from daily friction. It is also prone to tarnishing when exposed to sweat, lotions, or humidity. We delve deeper into this in our guide on what you should know about gold-plated jewelry.

PVD, in contrast, creates a molecular bond. The coating becomes one with the base metal, not just a layer on top. This makes the surface incredibly resistant to the scratches, dings, and corrosion that plague traditional plating.

PVD Versus Rhodium Plating

Rhodium plating is commonly used to give white gold and sterling silver a bright, mirror-like shine and protect it from tarnishing. Like gold plating, it is an electro-chemical process. Although rhodium is a durable precious metal, the coating is still just a thin layer.

This means it is prone to wearing off, especially on high-contact items like rings and bracelets, eventually requiring replating to restore its appearance. PVD coatings offer a much more permanent solution, providing lasting color and protection without the need for reapplication.

Choosing the right coating is a business decision that balances aesthetics, durability, and cost. While traditional methods have a place in fast fashion, PVD stands out for creating the long-lasting, affordable luxury that modern consumers seek.

To understand the PVD advantage, consider the analogy of car finishes: the difference between wax and ceramic coating. One offers a temporary shine, while the other provides durable, long-term protection. Both scenarios involve weighing initial appearance against real-world performance and long-term value.

The table below provides a quick comparison to help you make informed buying decisions for your business.

Jewelry Coating Methods: A Comparison for Retailers

| Coating Method | Durability and Lifespan | Hypoallergenic Quality | Typical Cost Factor | Best For |

|---|---|---|---|---|

| PVD Coating | Excellent. Molecular bond is highly resistant to scratches, tarnish, and fading. Lasts for years with proper care. | Excellent. The coating is biocompatible and inert, creating a safe barrier for sensitive skin. | Moderate. Higher upfront cost than plating, but excellent long-term value due to longevity. | Daily-wear jewelry, waterproof pieces, and offering hypoallergenic, high-value collections. |

| Gold Plating | Low to Moderate. A thin surface layer that is prone to chipping, fading, and tarnishing within months. | Variable. Depends heavily on the base metal underneath; often contains nickel, a common allergen. | Low. The most affordable option, making it suitable for fast-fashion or costume jewelry. | Low-cost fashion items where longevity is not the primary concern. |

| Rhodium Plating | Moderate. Provides a hard, tarnish-resistant layer but will wear off over time, especially on rings. | Good. Rhodium itself is hypoallergenic, but the protection is lost once the plating wears away. | Moderate to High. Rhodium is a precious metal, making this process more expensive than gold plating. | Giving white gold or sterling silver a bright, protective finish that requires eventual reapplication. |

How to Source High-Quality PVD Jewelry

Now that you understand what PVD coating is and why it's a superior choice for jewelry, the next crucial step is finding reliable suppliers who can deliver high-quality, affordable PVD products.

It's important to recognize that not all PVD finishes are created equal. The final quality depends on the supplier's process, equipment, and the materials used. Successful sourcing separates a reputable business from one plagued by quality issues and returns.

The foundation of a great PVD-coated piece is the base metal. A premium finish cannot compensate for a cheap, flimsy base. For jewelry and fashion accessories, the best choices are stainless steel (specifically surgical-grade 316L) and titanium. Both are durable, corrosion-resistant, and hypoallergenic—the ideal canvas for a PVD coating.

When vetting a new supplier, your first question should be about their base metals. Reputable partners are transparent and can provide documentation to verify their materials. Do not compromise on this; a quality base is essential for product longevity. To learn more, explore our guide on why gold stainless steel necklaces are such a durable and popular choice for businesses.

Vetting Suppliers and Their PVD Process

Once you've confirmed the base metal is solid, investigate their PVD coating process. You don't need a degree in materials science, but asking informed questions demonstrates that you are a serious buyer who will not accept subpar products.

Here are key questions to ask any potential supplier:

- What materials do you use for the coating itself? Look for answers like titanium nitride (for gold tones) or zirconium nitride. These are industry standards for durable, vibrant finishes.

- Can you describe your quality control process? A professional manufacturer will mention multi-step checks, such as adhesion tests (to ensure the coating won't peel) and color consistency analysis across batches.

- Do you have any third-party certifications? Certifications like SGS testing are a strong indicator of quality and safety, providing third-party verification of material composition.

Sourcing is about building partnerships, not just finding the lowest price. A supplier who openly discusses their process and materials is more likely to deliver the consistent quality your business and customers expect.

The Strategic Advantage of No MOQ

For small businesses and growing brands, Minimum Order Quantities (MOQs) are a significant barrier. High MOQs tie up capital in a single style, creating risk when testing new designs or trends. Partnering with a supplier who offers no MOQ is a major strategic advantage.

Sourcing from a no-MOQ supplier allows your business to:

- Test New Products with Low Risk: Order a small batch of a new design to gauge market response. If it's a success, you can invest more. If not, your financial exposure is minimal.

- Offer Greater Variety: You can stock a wider range of products without requiring a large warehouse or a substantial upfront investment.

- Improve Cash Flow: Purchase inventory as needed, keeping your capital free for marketing, branding, and other growth initiatives.

The market for PVD coatings is expanding rapidly. Valued at over USD 22 billion in 2024, it is projected to reach USD 33.1 billion by 2029. This growth is driven by consumer demand for durable, affordable luxury goods like jewelry. This trend works in your favor, as more suppliers enter the market, increasing competition and access for businesses like yours. You can read more about this expanding market and its forecast to understand how it is shaping sourcing trends.

Answering Your Customers' PVD Jewelry Questions

When a customer asks about PVD-coated jewelry, providing clear, confident answers not only secures a sale but also builds trust and establishes you as an expert. Here are the most common questions you'll encounter, with answers to help you educate your customers and set accurate expectations.

We'll cover everything from the lifespan of a PVD finish to whether it contains real gold, giving you the information needed to empower your clientele.

How Long Does PVD Coating Really Last?

This is often the first question, as many consumers have been disappointed by traditional gold plating that wears off quickly. PVD is in a different class entirely.

With basic care, a quality PVD finish on a stainless steel or titanium base can last for years without fading or tarnishing. It is designed for longevity.

For high-contact items like rings and bracelets, you can confidently tell customers to expect the finish to last for several years. For pieces with less daily friction, such as necklaces and earrings, it can last even longer. This durability is the primary selling point of PVD and what distinguishes it from fast-fashion jewelry.

Is PVD Coating Real Gold?

This is an excellent question, and the answer highlights the ingenuity of the technology. The short answer is: usually no, but sometimes yes.

Most gold-tone PVD coatings derive their color from titanium nitride (TiN), a very hard, gold-colored ceramic material that is incredibly tough and corrosion-resistant. By adjusting the process, technicians can achieve tones that mimic 14K, 18K, and rose gold without using any precious metal.

However, some high-end PVD processes do use real gold. This is typically a multi-step process: first, a hard base layer like titanium nitride is applied for durability, followed by a very thin, genuine gold layer deposited on top using PVD.

This method combines the durability of a ceramic coating with the authentic beauty of real gold. It is more expensive but demonstrates the versatility of PVD technology.

Is PVD Coating Hypoallergenic and Safe for Sensitive Skin?

Absolutely, and this is a significant benefit for your customers. The primary materials used in PVD, such as titanium nitride and zirconium nitride, are biocompatible and inert.

This means they do not react with the skin, making them exceptionally safe for people with metal sensitivities, particularly to nickel. You can confidently market your PVD jewelry as a hypoallergenic option, expanding your customer base to include those who have struggled to find jewelry that doesn't cause a reaction. The coating acts as a safe barrier between the skin and the base metal.

Can PVD Coated Jewelry Get Wet?

Yes! PVD jewelry is both waterproof and sweatproof, making it ideal for everyday wear. The coating creates a dense, non-porous shield that is highly resistant to the corrosion and tarnish that moisture can cause.

Your customers can wear their pieces to the gym, in the shower, or on vacation without worrying about the color fading. This practical advantage over delicate plated items makes it "wearable luxury" that fits a modern, active lifestyle.

How Do You Care for PVD Jewelry?

One of the best features of PVD jewelry is its low maintenance. However, providing a few simple care tips will help customers keep their pieces looking pristine for years.

The advice is simple:

- Keep It Clean: A quick wipe with a soft, lint-free cloth is usually sufficient. For a deeper clean, use mild soap and warm water, then rinse and dry thoroughly.

- Avoid Harsh Chemicals: While the coating is durable, it's best to avoid direct contact with bleach, harsh cleaning agents, or heavy chlorine.

- Store It Smart: To prevent scratches from other items, store each piece separately in a soft pouch or jewelry box when not in use.

While these tips are specific to PVD, having knowledge of general gold jewelry cleaning and care will further establish you as a trusted resource for your customers.

Are All PVD Coatings the Same Quality?

No, not at all. This is where your sourcing strategy is critical. The quality of a PVD finish depends on the supplier's expertise, their equipment, the purity of the coating materials, and, most importantly, the quality of the base metal. A perfect PVD coating on a poor-quality base is ineffective.

This is why partnering with reputable suppliers who use high-grade stainless steel or titanium is non-negotiable. A reliable partner will be transparent about their process and materials, ensuring you receive a beautiful, consistent product every time—the key to building a collection that reflects your brand's commitment to quality.

Ready to build a collection of beautiful, durable, and profitable jewelry that your customers will love? At JewelryBuyDirect, we offer over 120,000 high-quality, PVD-coated styles with no minimum order quantity, factory-direct pricing, and free worldwide shipping on orders over $150. Explore our catalog today!

to show code

to show code