Arthur Lynch | Wed Nov 19 2025

Packaging for Rings Ultimate Guide

Packaging for rings transforms a small piece into a memorable brand moment. A crisp box, soft pouch or sleek tube doesn’t simply hold your product; it sets first impressions and guarantees each ring arrives flawless. For businesses sourcing high quality and affordable jewelry and fashion accessories, packaging plays a critical role in delivering products that align with brand standards and customer expectations.

Why Packaging For Rings Is Essential

A ring box feels like a handshake. It speaks volumes about quality before the lid even lifts.

- Protection against scratches and impacts during transit

- Instant brand recognition through color, texture, and finishing

- An elevated unboxing experience that encourages repeat purchases

Packaging speaks for your brand before the product does.

Case Study: An independent jeweler swapped basic tubes for velvet-lined gift boxes and saw a 20% boost in repeat sales.

- The tactile upgrade created an emotional connection

- Luxury-level interiors justified a 15% price increase

Packaging And Brand Perception

Color choices and textures tell a story. Luxury labels often lean on rich velvet or suede interiors, while modern brands favor smooth matte exteriors. That difference in feel and finish directly influences perceived value.

The global jewelry packaging market in 2023 was valued at USD 10.5 billion, and it is projected to reach USD 15.8 billion by 2032, growing at a 4.5% CAGR.

Learn more about these market findings on Dataintelo.

Optimizing Online Sales

For brands selling rings online, selecting the right e-commerce packaging solutions is essential for product protection, brand building, and boosting efficiency.

- Use a sturdy outer mailer to guard against shipping mishaps

- Include branded inner boxes to reinforce identity upon opening

- Add eco-friendly inserts to appeal to sustainability-minded customers

Building Customer Loyalty

Thoughtful packaging turns first-time buyers into advocates. Each carefully wrapped ring reinforces a positive experience and invites customers back. This approach resonates especially well for businesses offering both jewelry and fashion accessories, demonstrating a commitment to quality and cost-effectiveness.

Smart packaging reduces returns from damaged items, cutting handling costs and boosting profit margins. It also signals your sourcing philosophy, showing business buyers that you hold quality and affordability in balance.

Next, we’ll explore the building blocks of ring packaging—cushioning, structure, and storytelling—to guide your sourcing strategy.

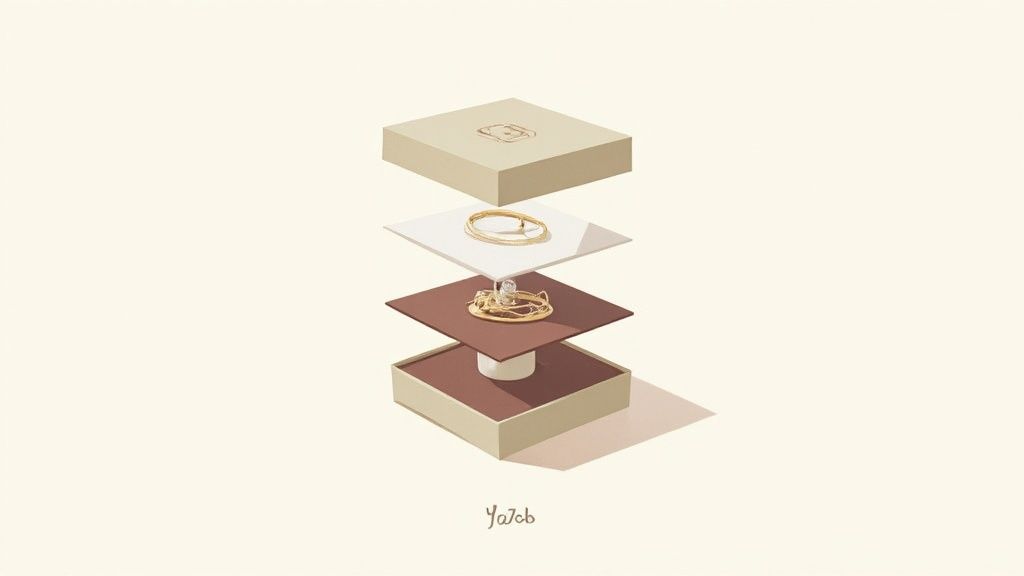

Building Blocks Of Ring Packaging

A ring box is more than a container. It’s the first handshake between your brand and your customer—offering protection, structure, and a visual promise. When these elements align, the unboxing moment becomes memorable and reinforces your story.

- Cushioning absorbs shocks and prevents scratches

- Structure stands up to stacking and transit pressures

- Visual Appeal tells a story through color, texture, and finish

Choosing the right insert can make all the difference. Foam, velvet, or suede each cradle the jewelry in a unique way.

For instance, a memory foam insert can absorb up to 90% of transit impacts. On the structure side, rigid walls, magnetic closures, and reinforced corners keep the box intact no matter how many hands it passes through.

Think of your packaging as nesting dolls—each layer protects and unveils the next. One small jeweler added a slim padded sleeve under its main box and saw damage claims drop by 30%.

Packaging is like armor: the better the fit, the stronger the defense.

Exploring Cushioning Materials

Velvet and suede cushions bring a touch of luxury to the moment customers lift the lid. They also keep rings perfectly centered, highlighting the piece.

Alternatively, recycled paper inserts can appeal to eco-minded buyers. This choice blends practicality with your sustainability goals.

Key Insight Cushioned packaging can reduce product damage claims by up to 75%.

Seals add a final layer of confidence. A simple ribbon or custom sticker signals tamper evidence and ensures your product arrives exactly as intended. Heat seals or specialty tapes boost security even further.

- Ribbon ties create an elegant unboxing feel

- Custom stickers reinforce branding while sealing closures

- Tamper-evident tapes reveal any unwanted opening

Finishing Touches For Visual Appeal

Soft-touch coatings and matte laminations invite customers to feel quality before they open the box. Foil stamping or embossing can pick out your logo with a subtle gleam, often justifying a 10–15% price premium in the eyes of buyers.

By layering cushioning, seals, and finishes, you’ll deliver ring packaging that protects, delights, and tells your brand’s story—every single time.

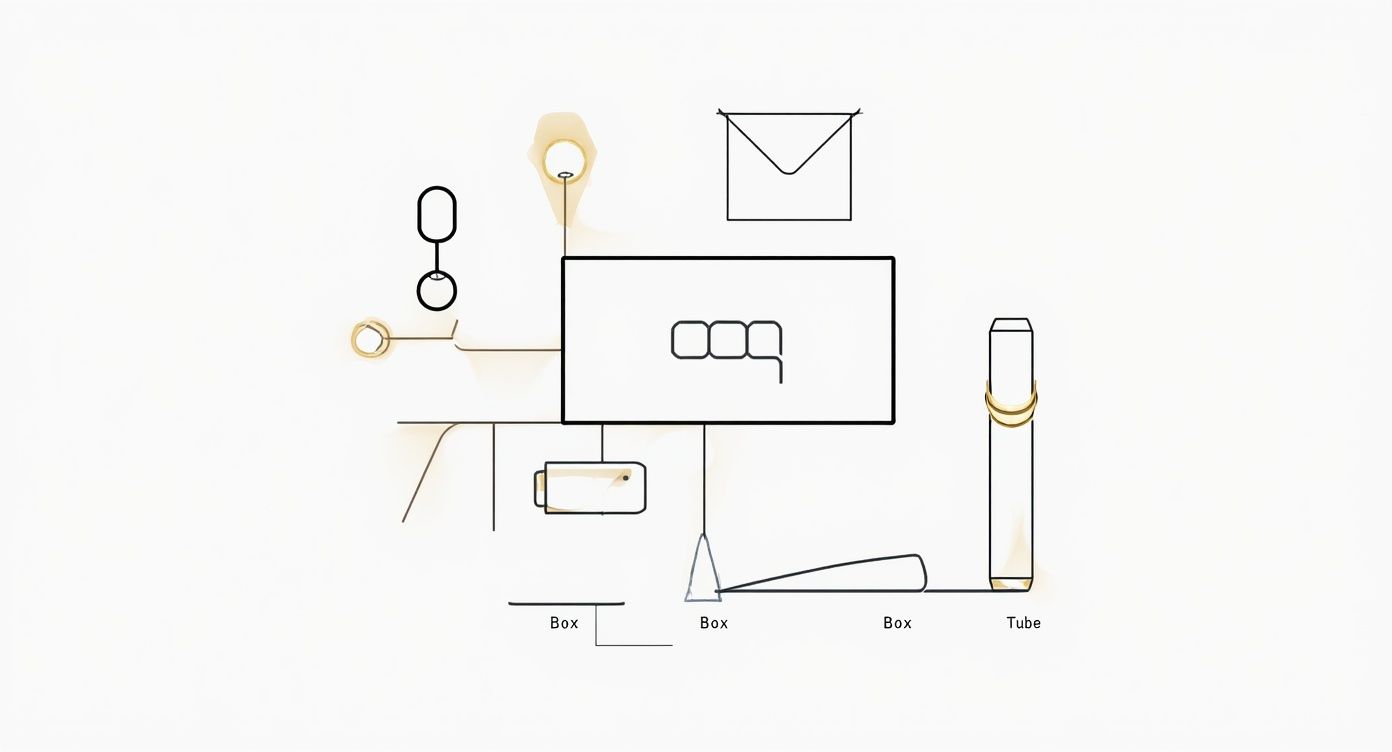

Choosing Materials And Styles For Ring Packaging

Selecting packaging feels a lot like picking the perfect outfit for a special occasion—it speaks before the main event. A rigid box brings structure and a sense of occasion. A soft pouch adds a whisper of luxury. And a tube offers a streamlined, modern reveal.

Think of boxes as your brand’s elegant tuxedo: they stand tall and stay secure. Pouches, on the other hand, are like velvet gloves—soft to the touch and intimate. Tubes cut a sleek silhouette, perfect for brands embracing minimalism.

- Boxes provide sturdy protection and a high-end appearance.

- Pouches use materials such as velvet or satin to create a tactile, upscale feel.

- Tubes often arrive in paperboard or plastic for a clean, contemporary unboxing.

Comparing Packaging Material Options

Before you decide on a format, here’s a quick snapshot of how boxes, pouches, and tubes stack up.

Comparison Of Ring Packaging Types

| Packaging Type | Durability | Approximate Cost | Sustainability | Ideal Use |

|---|---|---|---|---|

| Box | High crush strength | Moderate | Recyclable paperboard | Premium gifts and displays |

| Pouch | Soft impact cushion | Low | Natural fibers or blends | Bridal and luxury items |

| Tube | Moderate | Low to moderate | Paper or plastic options | Modern and minimalist lines |

Matching Styles To Brand And Budget

Your packaging material should tell your brand’s story and fit your wallet. An independent boutique might lean on custom‐printed paperboard to keep costs around $1–$3 per unit. A luxury jeweler could select a handcrafted wooden box with velvet lining, budgeting $5+ for each premium piece.

- Define Your Brand Tone: Playful, minimalist, vintage, or artisanal.

- Set A Per-Unit Budget: Allocate funds early to avoid surprises.

- Order Sample Swatches: Feel, test, and photograph materials in real-world light.

Thoughtful material choices bridge the gap between beauty and function, making every unboxing a memorable moment.

Finalize your decision with a quick checklist:

- Does the material reflect your visual identity?

- Can it survive shipping knocks and tumbles?

- Is it priced within your wholesale packaging budget?

- Will it satisfy sustainability goals and appeal to eco-minded shoppers?

By pairing the right format—box, pouch, or tube—with materials that echo your brand voice and budget constraints, you’ll deliver an unboxing experience that delights customers and builds loyalty.

Check out our guide on packaging boxes for jewellery to explore more design ideas and tips in our article.

The global jewelry box market, including ring-specific packaging, is set to expand from USD 3,264.0 million in 2025 to USD 5,166.7 million by 2035 at a 4.7% CAGR. For a deeper dive, see the full report from Future Market Insights.

Crafting Brand-Driven Ring Packaging

Think of ring packaging as a brand’s red carpet. The minute someone spots your box, they’re already forming expectations. With thoughtful design, you can ignite excitement and hint at the craftsmanship inside.

Color choices play a starring role. A rich burgundy whispers luxury, while a deep navy signals trust. Select shades that resonate with your brand’s story.

Where you place your logo matters just as much. Centering it on the lid draws attention instantly. Nestling it on the interior delivers a delightful “secret reveal” that keeps your name top of mind.

Finish techniques turn simple cartons into tactile memories:

- Foil Stamping adds metallic highlights, boosting perceived value by 10–15%.

- Embossing lifts logos off the surface, creating a three-dimensional feel.

- Soft-Touch Coatings invite hands to linger, hinting at premium quality.

These details weave texture and shine into your brand narrative.

Incorporating Texture And Finish

A small jeweler swapped a matte box for a soft-touch design and saw unboxing clips climb by 20%. Pairing foil with embossing adds depth, catching light in unexpected ways. It’s about striking a balance between visual flair, production limits, and budget.

Collaborating With Designers

Collaborating closely with a packaging expert ensures your vision comes to life. Start by:

- Sharing mood boards packed with color swatches and texture ideas.

- Reviewing digital mock-ups to nail logo scale and placement.

- Ordering a handful of prototypes for hands-on checks before going big.

This hands-on process aligns your ring packaging with both brand vision and real-world needs.

“Texture and finishes are the silent storytellers of your brand,” notes an industry veteran.

Validating Your Packaging Design

Early feedback helps steer clear of costly missteps. Invite a small group to share impressions on:

- Color accuracy and emotional reaction

- Logo clarity and placement

- Hand-feel of each finish

Run simple A/B comparisons with box samples:

- Matte finish with silver foil stamping

- Soft-touch coating with gold embossing

Inspect these under daylight and office lights. Check embossing depth and foil adhesion on sample runs to confirm durability. This iterative loop not only saves time but delights customers.

Below is a decision tree illustrating how brand questions lead to choosing a box, pouch, or tube based on brand voice and customer preferences.

This chart visualizes a left-to-right flow of brand attributes guiding the ideal packaging format choice.

Key insight: matching packaging formats to customer preferences can boost satisfaction by 30% in pilot tests.

Explore more packaging ideas for jewelry in our article on packaging ideas for jewelry.

Optimizing Cost, Quality And Sustainability

Finding the balance between keeping costs in check and upholding your brand’s values can feel like walking a tightrope. With a few clever moves, you can secure ring packaging that looks great, protects your product, and respects your budget. For businesses balancing jewelry and fashion accessory sourcing, batch orders and modular inserts help keep costs competitive across your product range.

For instance, batch orders unlock volume discounts and drive down your per-unit price. Similarly, modular inserts let you swap components for different ring sizes—no extra tooling fees required.

- Batch Orders trigger better pricing tiers

- Modular Inserts save on setup and tooling

- Recycled board with PLA liners reduces waste and keeps costs low

Evaluating Per Unit Costs And Impact

Start by listing every cost—materials, labor, shipping—then assign each option an eco-score: recyclable, compostable, or neither.

For context, in 2023 rigid plastics made up 31.4% of packaging use, flexible at 30.5%, and paper/board at 15.2%. The industry is shifting toward biodegradable and compostable options Discover more insights about packaging statistics.

Key Insight Small shifts to biodegradable liners can cut landfill waste by up to 40% and win over eco-minded customers.

Choosing Eco Friendly Materials

Recycled paperboard and molded pulp carry your rings with minimal carbon output and excellent rigidity. Cornstarch-based bioplastics offer a similar feel to traditional plastics but break down naturally.

To polish your labels, inks, and coatings, explore sustainable printing practices.

| Tactic | Cost Impact | Sustainability Rating |

|---|---|---|

| Recycled Paperboard | Moderate (+$0.10) | High (90% recycled) |

| PLA Bioplastic Liners | Low (+$0.05) | Medium (compostable) |

| Modular Insert Kits | Low (-$0.08) | High (reusable) |

Implementing A Sustainable Framework

Think of this like a recipe. First, audit your current packaging and pinpoint waste hotspots. Next, set clear targets for cost cuts and recyclability.

- Gather samples from multiple suppliers

- Run small pilot shipments to test strength and appeal

- Compare quotes and refine your goals

One boutique jeweler cut waste disposal fees by 25% after swapping to molded pulp inserts. Meanwhile, another brand saw loyalty scores climb by 18% over six months.

Measuring Success Over Time

Track metrics such as cost per unit, percentage of material waste, and customer feedback on packaging. Revisit your sourcing strategy each quarter to factor in new materials and price updates.

Over several cycles, you could shave costs by up to 15% while staying true to your brand’s promise. Start experimenting today.

Sourcing Wholesale Packaging For Rings

Once you’ve settled on materials and worked through your budget, the next big step is finding the right supplier. Think of this phase as a roadmap that takes you from first inquiry all the way to delivery.

- Lead Times: Typical windows for production and shipping

- Sample Policies: Costs, turnarounds, and any revision limits

- Printing Capabilities: Color precision, imprint methods, finish options

- Minimum Order Quantity (MOQ): Order levels that trigger better pricing

- Supplier Catalog Diversity: Look for partners who can supply both packaging solutions and display accessories, keeping procurement streamlined and cost-effective

Initial Manufacturer Outreach

To kick things off, narrow your list to 3–5 suppliers who specialize in ring packaging. Trade shows, industry referrals, and online directories are great hunting grounds.

Look for vendors who match both your quality requirements and your cost parameters. Ask for:

- Real-world tests on material strength and durability

- Color swatches to confirm print accuracy

- Sample boxes to check fit, finish, and overall craftsmanship

Case Study Brand Journey

Take the example of RingCraft, a boutique jewelry label. They reached out to three manufacturers in week one and had their hands on pre-production samples by week three.

- Inquiry Sent – Week 1

- Sample Arrival – Week 3

- Quote Negotiation – Week 4

- Pre-production Approval – Week 5

- Bulk Production – Weeks 6–8

In total, RingCraft saw a 6–8 week cycle from the first email to the shipment hitting their warehouse.

Negotiating Terms And Pricing

When quotes begin rolling in, dive into the numbers. Compare unit costs, but don’t forget about value-added services like custom inserts or branded tissue. Consider bundling packaging and fashion accessory orders to unlock deeper volume discounts.

See where you can save:

- Volume Tiers that drop the per-unit price

- Payment Timings that keep your cash flow healthy

- Customization Allowances for logos, finishes, and inserts

“One small brand cut its per-unit cost by 15% by consolidating orders and adjusting its reorder schedule.”

If you’d like more tips on planning your bulk-buy strategy, check out our guide on packaging for jewelry wholesale.

Remember to get every fee in writing—tooling charges, warehousing, and any extras. And always ask for a detailed production schedule so your marketing and inventory teams stay in sync.

In 2023, 73% of jewelry brands said supplier reliability was their top priority.

Finalizing Orders And Quality Checks

Before green-lighting a big run, request a final pre-production sample. Then, use a simple checklist to confirm:

- Dimensions match your specs

- Print registration is spot on

- Box structure holds up under typical use

| Supplier | Lead Time | MOQ | Price/Unit | Print Support |

|---|---|---|---|---|

| Vendor A | 4 weeks | 500 | $1.20 | Full color |

| Vendor B | 3 weeks | 1,000 | $1.05 | Limited |

With these steps in place, you’ll sidestep costly surprises and build a partnership that scales as your brand grows.

Ring Packaging FAQ

Here are actionable answers to key questions on ring packaging. These insights help brands make smarter choices and save money.

What Is The Minimum Order Quantity For Custom Ring Boxes?

In most cases, suppliers require a 250–500 unit MOQ for standard designs. Keep in mind that unit pricing tends to fall as your order grows.

Key MOQ Considerations:

- 500+ units often unlock bulk pricing.

- Complex designs may raise MOQ or incur tooling costs.

- Samples (usually 10–20 pieces) let you check materials before you commit.

What’s The Best Way To Source Sustainable Materials On A Tight Budget?

Try blending recycled paperboard with affordable PLA liners. You often see a 5–10% drop in material costs without losing quality.

“Small shifts toward sustainable materials can boost brand perception and cut waste fees,” advises a packaging consultant.

Sample Testing Process

What’s The Best Way To Test Samples Before Placing A Large Order?

Run a series of real-world tests to make sure your packaging holds up.

- Drop tests from 1.2m to assess strength.

- Color checks with Pantone swatches under daylight.

- Fit trials using your target ring sizes for a snug hold.

Which File Formats Do Designers Need For Printing?

Always supply high-resolution vector files—think AI, EPS, or PDF—with at least 300 DPI for any embedded images. That way, logos stay sharp and colors stay true.

How Do You Handle Communication Breakdowns With Overseas Suppliers?

Set up regular video check-ins and rely on project-tracking tools for live updates. Clear specifications, shared samples, and an open feedback loop go a long way in avoiding mix-ups.

With these tips, you’ll streamline decisions and dodge common ring-packaging pitfalls. Next, partner with a dependable wholesaler to lock in quality at scale.

For seamless sourcing, explore JewelryBuyDirect today.

to show code

to show code