Arthur Lynch | Mon Dec 01 2025

A Business Guide to Sourcing Gold Electroplated Jewelry

Gold electroplated jewelry strikes the perfect balance between the look of luxury and a price point that makes sense for your business. For any brand sourcing fashion accessories, understanding this category is crucial.

The concept is simple: a strong, affordable base metal is coated with a beautiful, durable outer layer of real gold. The result? You can offer your customers stunning, on-trend pieces that look premium, without the high cost of solid gold. This is a massive win for businesses aiming to provide both quality and affordability.

A Business Guide to Gold Electroplated Jewelry

If you're running a business in the fashion accessories world, mastering the sourcing of gold electroplated jewelry is your key to building a profitable collection. It’s about more than just picking attractive designs; it's about identifying products that deliver real value, durability, and a style that keeps your customers coming back.

This guide will walk you through the essentials of sourcing. We’ll cover the science that creates that incredible shine and the practical steps for finding high-quality, affordable pieces your customers will love. The goal is to move beyond the basics and give you the confidence to make smart purchasing decisions. When you can spot quality, you can build a collection that perfectly balances cost with longevity—the secret to success in this competitive market. Of course, a great collection is just one piece of the puzzle; for lasting success, it's also about scaling an ecommerce business effectively.

The Growing Market for Plated Jewelry

The demand for "accessible luxury" is not a fleeting trend; it’s a fundamental shift in consumer behavior. Your customers want the look of fine jewelry for everyday wear, and gold electroplated pieces are the perfect solution. This growing demand is fueling significant market expansion.

The global market for precious metal plating, which includes gold electroplated jewelry, was valued at USD 240.90 million in 2024. That number is expected to climb to USD 393.38 million by 2033. This isn't a fluke; it's steady growth driven by the beauty and widespread use of gold plating in creating affordable, high-quality jewelry. For a deeper dive into the numbers, check out the precious metal plating market trends on Straits Research.

Why Sourcing Matters for Your Business

Sourcing is the foundation of your jewelry business. The quality of the products you procure directly shapes your brand's reputation, customer satisfaction, and, ultimately, your profitability. Getting this right from the start is absolutely critical for long-term success.

By focusing on sourcing high-quality pieces from the start, you reduce the risk of customer complaints, minimize returns, and build a loyal following that trusts your brand's commitment to excellence.

That's what this guide is all about—giving you the knowledge to succeed. You’ll learn how to vet suppliers, what to look for in material specifications, and how to select jewelry that truly reflects your brand's promise of affordable quality. For more on this, explore the benefits of sourcing factory-direct jewelry.

The Science Behind the Shine

You don't need a chemistry degree to source fantastic gold electroplated jewelry, but understanding the science behind that brilliant finish is a major advantage for your business. It helps you ask suppliers the right questions and, more importantly, spot the difference between a fleeting trend and a lasting, high-quality product for your inventory.

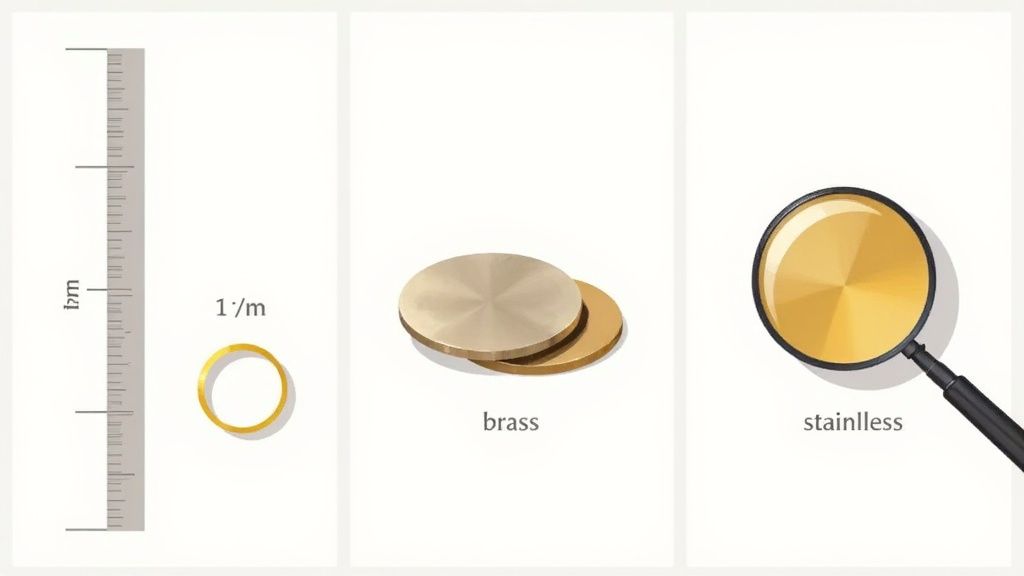

Think of it like giving a car a high-end, custom paint job. The base metal—usually something sturdy and affordable like brass, copper, or stainless steel—is the car's body. The shimmering gold is the paint. The entire process, called electroplating, is the meticulous work that ensures the finish is flawless, durable, and appealing to customers.

It all starts with an impeccably clean base. The base metal piece must be completely free of oils, dust, or any imperfections. Just as you wouldn't paint over a dirty surface, a manufacturer must get the base metal pristine so the gold layer adheres properly. Skipping this crucial first step leads to quality issues like bubbling, flaking, or peeling—all of which can damage your brand's reputation.

The Electroplating Process Step-by-Step

Once the base metal is perfectly prepped, it's ready for its golden transformation. The process takes place in an electrolytic solution, a special liquid bath containing dissolved gold ions—microscopic particles of real gold.

The process is precise:

-

The Setup: The base metal jewelry is submerged in this gold-rich liquid. A piece of solid gold is also placed in the bath to act as the anode (the source of gold).

-

The Current: An electric current is introduced. The base metal jewelry is given a negative charge (making it the cathode), while the gold ions in the solution have a positive charge.

-

The Transformation: Opposites attract. The positively charged gold ions are drawn through the solution and bond, atom by atom, onto the negatively charged surface of the jewelry, creating a thin, perfectly uniform layer of real gold.

This process is incredibly controlled. The thickness and evenness of the gold layer are determined by the strength of the electric current and the duration the piece remains in the bath. A skilled manufacturer can control this down to the micron (one-millionth of a meter) to achieve the exact quality, durability, and cost-effectiveness you need for your product line.

For instance, understanding how different base metals react is key. A protective plating is especially important for metals like sterling silver, which you can learn more about in our guide discussing if sterling silver tarnishes over time.

Why Quality Control in Plating Is Everything

Not all gold plating is created equal. The difference between a piece that looks great for years and one that dulls in weeks often comes down to the manufacturer's attention to detail. Variables like the chemical makeup of the bath, its temperature, and the current density must be constantly monitored to ensure consistent quality.

This is the fundamental journey for any jewelry business—from understanding the product to making a profit.

Mastering each step, especially sourcing, is what sets successful businesses apart.

The demand for the very chemicals used in this process tells a powerful story. The global market for gold plating chemicals was valued at around USD 545.8 million in 2024 and is expected to climb to USD 738.8 million by 2031. This isn't just a statistic; it shows a huge and growing consumer appetite for affordable jewelry with a premium look. For a business, this signals a stable, expanding market with a reliable supply chain.

Key Takeaway: A supplier who can confidently discuss their electroplating process—from bath maintenance and quality checks to the specific plating thickness—is far more likely to deliver a consistent, high-quality product that your business can rely on.

When you understand the science, you demystify the product. You're no longer just a buyer; you're an informed sourcing professional, ready to build an inventory that shines—both for your customers and for your bottom line.

How to Identify High-Quality Plated Jewelry

When sourcing gold electroplated jewelry, learning to spot quality is the bedrock of your brand's reputation. Your customers trust you to deliver beautiful, durable pieces. Knowing the difference between a lasting favorite and a quick disappointment is what will set your business apart and drive repeat purchases.

The good news is you don't need to be a professional jeweler to do this. By focusing on three key areas—plating thickness, the base metal, and the overall finish—you can confidently evaluate samples and build an inventory that signals high quality and great value. Mastering these checkpoints will help you curate a collection that perfectly balances affordability with longevity.

Plating Thickness The Ultimate Durability Test

The single biggest factor determining the longevity of gold-plated jewelry is the thickness of its gold layer. This is measured in microns (μm). A thicker layer means more gold, which translates directly to greater durability, tarnish resistance, and a longer-lasting shine.

Think of it like paint on a wall. A single, thin coat might look okay initially but will scuff and fade quickly. A couple of thick, high-quality coats, however, can withstand daily life for years. The same logic applies to your jewelry inventory.

For any business sourcing these products, understanding microns is key to matching jewelry with the right price point and customer expectations.

- Flash Plating (Under 0.5 microns): This is a very thin, decorative layer. It's often used for low-cost, fast-fashion items with a short intended lifespan. These pieces are best for minimal-wear items like earrings and should be marketed as such.

- Standard Plating (0.5 - 1.0 micron): This range offers a great balance of affordability and durability for your business. A 1.0-micron plating is a solid, reliable choice for everyday rings, necklaces, and bracelets that see regular wear.

- Heavy Plating (1.5 - 2.5+ microns): Anything in this range is considered premium quality. These pieces boast excellent durability and are perfect for higher-end collections designed to last for years with proper care.

When communicating with suppliers, always ask for the specific micron thickness. A transparent, reputable supplier will provide this information readily, as it's a primary indicator of their quality standards and helps you justify your retail pricing.

To help you decide what to stock, here's a quick reference guide connecting plating thickness to practical business applications.

Gold Plating Thickness and Business Application

| Plating Thickness (Microns) | Common Terminology | Durability Level | Recommended Jewelry Type for Business Stock |

|---|---|---|---|

| < 0.5 μm | Flash Plating | Low. Prone to fading and wear with minimal use. | Occasion-wear earrings, pendants, or promotional items where longevity isn't the primary selling point. Clearly label as delicate to manage customer expectations. |

| 0.5 - 1.0 μm | Standard Plating, Gold Plated | Medium. Withstands regular wear but not constant friction. | A solid choice for everyday necklaces and bracelets. A 1.0-micron thickness is the minimum recommended for rings. This is the sweet spot for balancing quality and affordable wholesale cost. |

| 1.5 - 2.5+ μm | Heavy Gold Plating, Vermeil (if over sterling silver) | High. Very durable and resistant to tarnish and wear. | Ideal for signature collections, high-contact items like chain bracelets, and pieces marketed as long-lasting investments. Supports a higher retail price point. |

Ultimately, knowing these numbers empowers you to make smarter sourcing decisions and be transparent with your customers about the quality they are purchasing.

The Importance of the Base Metal

The metal underneath the gold plating is the unsung hero of a quality piece. It provides the structure, weight, and hypoallergenic properties. A solid, well-chosen base metal ensures the jewelry won’t easily bend, break, or cause an adverse skin reaction.

For high-quality and affordable plated jewelry, the two most reliable base metals are brass and stainless steel.

- Brass: An alloy of copper and zinc, brass is a fantastic, cost-effective option. It's strong, resists corrosion, and gives jewelry a substantial, premium weight. Gold also adheres beautifully to brass, creating a smooth, durable finish.

- Stainless Steel: Known for its incredible strength and resistance to rust and tarnish, stainless steel is another top-tier choice. It is also naturally hypoallergenic, making it a safe and reliable option for customers with sensitive skin.

Sourcing Tip: When you receive samples, pay attention to the weight and feel. Quality base metals like brass and stainless steel give jewelry a satisfying heft that customers associate with value. Cheaper alloys often feel flimsy and light. Be wary of any supplier who is vague about their base metals or relies on nickel, a known skin allergen.

Inspecting the Finish and Craftsmanship

Finally, use your eyes. A simple visual inspection reveals volumes about manufacturing quality. A well-made piece of gold electroplated jewelry should have a flawless, even finish. Look for a uniform color and shine across the entire surface, with no dark spots, streaks, or patchy areas.

Check the details. Inspect hard-to-reach spots, like the inside of a ring or around the clasp of a necklace. If the plating looks thin or inconsistent, it signals a rushed, low-quality electroplating process. The surface should be perfectly smooth—no bumps, pits, or bubbles. A piece crafted with care will look and feel polished from every angle, ensuring customer satisfaction.

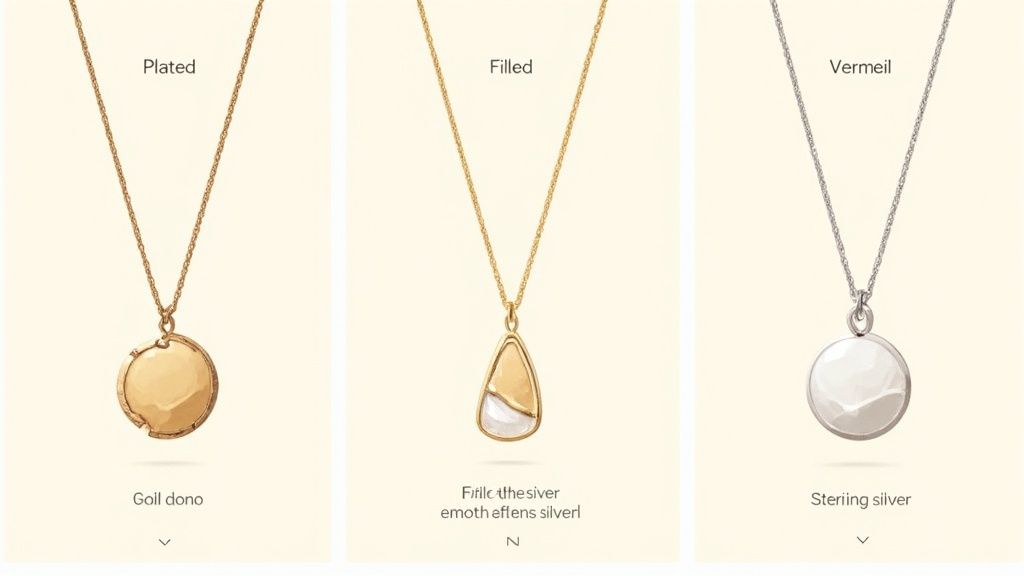

Plated vs Filled vs Vermeil Jewelry

When sourcing for your business, you'll encounter terms like "gold plated," "gold filled," and "gold vermeil." While they sound similar, they represent different levels of quality, durability, and cost. Understanding these distinctions is essential for building a diverse inventory that meets your brand's standards and your customers' expectations for quality and affordability.

Think of it this way for your business:

- Gold electroplating is like a beautiful coat of paint. It’s perfect for offering trendy, affordable fashion accessories.

- Gold-filled is more like a thick, durable laminate. It represents a higher-tier product built to last.

- Gold vermeil is a premium, specialized finish over sterling silver, ideal for a luxury segment of your collection.

Knowing the difference allows you to source strategically, market your products accurately, and build the trust that fosters customer loyalty.

Gold Electroplated Jewelry Explained

As we've covered, gold electroplated jewelry is made by depositing a thin layer of gold onto a base metal (like brass or stainless steel) using an electric current. This highly cost-effective method allows you to offer a wide variety of styles at accessible price points, maximizing your profit margins.

The key variable is the gold layer's thickness, measured in microns. While some pieces are "flash plated" (<0.5 microns) for decorative use, sourcing pieces with a more substantial plating of 1.0 to 2.5 microns ensures a longer lifespan and greater customer satisfaction.

The plating process often uses chemicals like gold potassium cyanide. The market for this compound was valued at USD 1,083.9 million in 2024, highlighting the massive scale of plated jewelry production worldwide. As a business owner, it's also wise to partner with suppliers who follow sustainable practices for managing manufacturing waste.

Gold Filled: A Durable Alternative

Gold-filled jewelry is manufactured differently. A thick sheet of gold is mechanically bonded to a base metal core (usually brass) with intense heat and pressure. This creates an incredibly strong and durable bond.

Here's the key differentiator for your business: by U.S. law, gold-filled items must contain at least 5% gold by weight. This is often 100 times more gold than a standard plated piece, which typically has less than 0.05% gold content.

This means you are offering a higher-tier product. Gold-filled pieces resist tarnish, won't flake or peel, and can last for years with care. It's the perfect choice for your core collection and for customers seeking long-lasting value at a mid-range price point.

Gold Vermeil: The Sterling Silver Standard

Gold vermeil (pronounced "ver-may") represents a luxury category. It's a standard defined by law, and to carry the gold vermeil label, a piece must meet three specific criteria:

- Base Metal: The core must be sterling silver (925).

- Gold Purity: The plating must be at least 10 karats.

- Gold Thickness: The plating must be a minimum of 2.5 microns thick.

This combination of a precious metal base and a heavy gold plating results in a durable, hypoallergenic piece perfect for customers with sensitive skin. To learn more, check out our guide on what vermeil jewelry is. Adding vermeil to your lineup can elevate your brand and attract customers looking for premium quality.

To help you make strategic sourcing decisions, here's a side-by-side comparison for wholesale buyers.

Comparison of Gold Jewelry Types for Wholesale Buyers

| Attribute | Gold Electroplated | Gold Filled | Gold Vermeil |

|---|---|---|---|

| Base Metal | Brass, Copper, Stainless Steel | Brass or Copper | Sterling Silver (925) |

| Gold Content | Minimal (<0.05% by weight) | At least 5% by weight | N/A (thickness-based) |

| Gold Layer | Thin (0.5-2.5 microns) | Very thick, pressure-bonded | Thick (2.5+ microns) |

| Durability | Lower; prone to tarnishing/wear | High; tarnish-resistant, long-lasting | High; durable with care |

| Price Point | Most Affordable | Mid-Range | Premium / High-End |

| Best For | Trendy, fashion-forward pieces with high turnover | Core collections, everyday wear for lasting value | High-quality, hypoallergenic designs for a premium offering |

Each of these options has a clear place in the market. By understanding their distinct attributes, you can strategically build a diverse and profitable jewelry collection that caters to every type of customer.

Finding the Right Wholesale Jewelry Suppliers

Knowing the difference between plating, filling, and vermeil is a huge step, but that knowledge is only powerful if you partner with suppliers who deliver what they promise. Finding the right wholesale source for your gold electroplated jewelry is the single most important part of building a successful, reputable business. It's about forging relationships with partners who meet your quality standards and consistently provide products that delight your customers.

A great supplier doesn’t just sell you a product; they become a critical part of your supply chain. You're looking for transparency, reliability, and the kind of quality that builds a trusted brand. The goal is to move past one-off orders and create lasting partnerships that support your business as it grows.

Identifying and Vetting Potential Suppliers

So, where do you start? The first step is knowing where to look and what to ask. Vetting a supplier is like interviewing a candidate for a critical role in your company—because that's what it is. You must be thorough, methodical, and clear about your expectations from the beginning.

Start by creating a shortlist of potential manufacturers or distributors who specialize in the kind of jewelry you want to sell. A supplier focused on high-quality brass or stainless steel bases will be a much better fit than one churning out low-grade alloys. Once you have a list, it's time to investigate.

Here’s a practical checklist for vetting suppliers:

- Request Technical Specifications: Ask for the details. A trustworthy supplier will provide a "spec sheet" for their products that clearly lists the base metal, plating thickness in microns, and gold karat used.

- Verify Certifications: Ask if their materials are SGS-certified or meet other international standards for safety, such as being lead-free and nickel-free. This is a non-negotiable step for customer safety and brand integrity.

- Inquire About Quality Control: Ask them to describe their internal QC process. How do they ensure consistency from one batch to the next? A good supplier will be proud to explain their methods.

This initial screening helps you filter out suppliers who are not transparent or cannot meet your baseline quality standards.

The Importance of Ordering Samples

Never place a bulk order without getting your hands on a sample first. Website photos can't convey the weight, feel, or true finish of a piece. Samples are your only chance to perform a real-world quality check and are an essential part of the sourcing process.

When your samples arrive, inspect them with a critical eye:

- Visual Inspection: Check for plating evenness. Look for blotchy areas, scratches, or rough spots, especially in tricky areas like clasps or stone settings.

- Wear Test: Wear the jewelry yourself for a few days. Does it feel comfortable? Does it snag on clothing? Most importantly, how does the gold finish hold up to daily activity?

- Weight and Feel: Does the piece have a satisfying weight, or does it feel flimsy and cheap? Quality base metals like brass and stainless steel provide a substantial feel that customers associate with value.

A sample is your best defense against poor quality. If a supplier is hesitant to provide samples or charges an unreasonable price, consider it a major red flag. Confident partners want you to be confident in their products.

Negotiating Terms and Building Relationships

Once you've found a supplier whose samples meet your standards, it's time to talk business. This is where you establish the foundation for a strong, long-term partnership. Key points to cover are pricing, Minimum Order Quantities (MOQs), and production lead times.

Many suppliers have an MOQ, which is the smallest order they will accept. If their MOQ is higher than you need, don't be afraid to negotiate. Some may be willing to accommodate a smaller trial order, especially if they see potential in your brand.

Building a good rapport from day one can lead to better terms, priority service, and a partner who is genuinely invested in your success. For sourcing overseas, this process can feel overwhelming, but you can utilize a sourcing agent in China to help navigate these conversations and vet factories on the ground. By approaching every interaction with professionalism and clear communication, you can build a supply chain you can actually count on.

A Few Common Questions

When you're building a wholesale jewelry business, you're bound to have questions. You're trying to find that sweet spot between quality, price, and what your customers will love. Let’s clear up some of the most common questions business owners have about sourcing gold electroplated jewelry so you can make smarter decisions for your brand.

How Long Does Gold Electroplated Jewelry Actually Last?

This is the big one, right? The lifespan of a gold electroplated piece really boils down to three things: how thick the plating is, what metal is underneath, and how your customer treats it. Think of it like paint on a car—a thicker, quality coat will handle a lot more wear and tear than a quick, cheap spray job.

A very thin layer, often called "flash plating" (under 0.5 microns), is mostly for looks and won't stand up to much abuse. It’s fine for a pair of earrings someone might only wear on special occasions, but it’s not built for the long haul. With gentle use, you might get a year out of it.

For pieces that get a lot of action—like rings, necklaces, and bracelets—you need something more substantial.

Look for a plating thickness between 1.0 and 2.5 microns. This is the sweet spot. Pieces in this range offer fantastic value and can last for several years with the right care, which is exactly what you need to build a happy, loyal customer base.

Is It Hypoallergenic?

Customer comfort is everything, so this is a critical question. Here’s the secret: it’s not the gold that causes a reaction, it’s usually the metal underneath it. The main culprit is almost always nickel, a cheap alloy that some manufacturers use to cut costs, which is notorious for causing skin irritation.

The solution is simple: make sure you're sourcing jewelry that is explicitly nickel-free. Reputable suppliers will use better base metals like brass, copper, or stainless steel that are known to be safe for sensitive skin.

When you're talking to a potential supplier, don't be shy. Ask for material spec sheets. A good partner will have no problem telling you exactly what’s in their products. Being transparent with your own customers by stating the base metal (e.g., "18k gold plated over brass") is a huge trust-builder.

What Care Instructions Should I Give My Customers?

A little education goes a long way. Giving your customers simple care instructions is a fantastic touch that shows you care about their purchase long after the sale. It extends the life of the jewelry and makes your brand look great. Tucking a small instruction card into your packaging is an easy win.

Here are the key tips to share:

- Keep It Dry: Tell them to take their jewelry off before showering, swimming, or working out. Lotions, perfumes, and hairsprays should also be applied before putting on their jewelry, as the chemicals can eat away at the plating.

- Store It Smart: A soft pouch or a separate spot in a jewelry box is best. This stops it from getting scratched by other pieces and reduces tarnish from exposure to the air.

- Clean It Gently: A soft, dry microfiber cloth is all they need. Warn them against using harsh chemical cleaners or abrasive cloths, which can literally strip the gold layer right off.

By empowering your customers with this know-how, you help them keep their pieces looking beautiful, which ultimately reflects back on the quality of your brand.

How Can I Test a Supplier’s Quality?

Never, ever commit to a big order blind. Your reputation is riding on the quality of your products, so you have to do your homework. Thankfully, there are some pretty straightforward ways to check if a supplier's gold electroplated jewelry is as good as they claim.

First, and most importantly, always order samples. A pretty picture online can hide a lot, from a flimsy feel to a blotchy finish. You need to see it, touch it, and wear it yourself.

From there, use a simple checklist to vet any potential partner before you invest serious money:

- Ask for the Tech Specs: A legitimate supplier will happily give you a "spec sheet" with all the details: the base metal, the exact plating thickness in microns, and the gold karat. If they’re vague, that’s a huge red flag.

- Do a Wear Test: Put the samples to the test. Wear a ring or bracelet for a solid week and see how it holds up to real life. Does it tarnish? Chip? Turn your skin green?

- Give It a Close Look: Inspect the pieces under a bright light. You're looking for a smooth, even finish. Check for pitting, bubbles, or weird dark spots, especially around tricky areas like clasps and joints.

- Ask About Their Process: Inquire about their quality control. Do they have any third-party certifications (like from SGS) that verify their materials and processes? It shows they take quality seriously.

Following these steps will help you filter out the duds and find reliable partners you can build your business with.

Ready to find high-quality, affordable jewelry that will keep your customers coming back? Check out the massive catalog at JewelryBuyDirect, where you'll find factory-direct pricing on tens of thousands of current styles. We have no minimum orders and fast, reliable shipping, making it easy to build the perfect collection for your store. Start sourcing with confidence at JewelryBuyDirect.com.

to show code

to show code